What is LED?

LEDs are low voltage light emitting diodes, requiring a constant DC (Direct current) voltage or current to operate the LED Chip efficiently throughout its lifetime. This is also required to protect the rated lifetime (hours) of the LED chip, and to operate the LED chip at its optimum performance (temperature).

Using a low voltage DC power supply enables the LEDs to be used on different power supplies, and ensures safe operation of the LED. Generally individual LEDs used for general lighting require lower DC power and several hundred mA of current, whereas LED chips connected in series require a much higher voltage.

When LEDS are connected to the mains voltage (AC – Alternating current) the LED or array of LEDS must be protected from the changes in current (AC) power. This constant change of voltage results in a change of current, which can cause the LED light output to change. The reason for this is that the light output from an LED is proportional to the current, and each LED is rated for a specific current range. If the current exceeds this range, the light emitted from the LED can increase, however the rated life of the LED may be effected due to the higher temperature that will result from the higher current.

How to choose the right Driver?

The LED chip requires a driver that can convert incoming AC power to the recommended DC voltage, and regulate the current flowing through the LED during operation. The driver converts AC power to low-voltage DC power required by the LEDs, and protects the LEDs from line-voltage fluctuations by monitoring the “loop current” of each LED chip, and adjusts the generated DC output to the minimum value needed to produce the highest forward voltage. Due to the input power is AC and the LED runs on DC, the AC current needs to be converted to DC by means of a “rectifier”.

Some LED lamps have rectifiers inbuilt into them, enabling the LED source to be used on old iron core transformers. However, if there is no inbuilt rectifier, the LED source then must be used in conjunction with a specific LED driver.

LUSION recommends that users should always check with manufacturers as to the compatibility of LED light sources, especially when it is intended to use the LED source in conjunction with, say, an iron core transformer rather than an LED driver.

What is Phase Dimming?

This method dims the light source by decreasing the power, which in turn decreases the amount of light emitted from the LED. It achieves this by “cutting “the phase of the AC current.

There are two (2) ways it can achieve this, by Leading Edge and Trailing edge dimming.

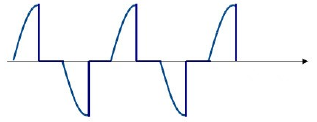

a. Leading Edge Dimming

More commonly known as “Triac” or dimming, this form of dimming was originally established for the

electronic dimming of incandescent light sources (GLS lamps) or low voltage magnetic transformers

used for 12v halogen lamps. Leading edge dimming shuts off the oscillating sine wave at the front of

the AC input. (Fig. 1) The down side of this method is that sometimes this can result in “buzzing” or

“humming” when dimming. In addition, when used for an LED lamp, the “rush” of input current when

dimming can cause damage to the electronic components, resulting in shorter life than expected of

the LED chip.

b. Trailing Edge Dimming

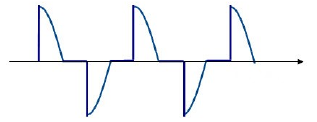

This is also called “TRIAC dimming”, but it is a reverse form of leading edge dimming, as it turns the

current off at the end of the AC input. (Fig. 2). Common for both electronic LED drivers and low

voltage transformers, trailing edge dimming has the advantage that it will not inject a high inrush

current, therefore avoiding the harmonic “buzzing” or “humming” common with leading edge dimmers.

Fig. 1 Leading edge dimming curve

Fig. 2 Trailing edge dimming curve

What is O-10V Analogue Dimming?

Originally 0-10V analogue dimming was more commonly used for early fluorescent dimming. Today, some LED fixtures are also designed for this dimming method.

The 0-10V dimmer is connected to the circuit in parallel, and dims the LED source simply by adjusting the input to the lamp by scaling the DC voltage at the dimming source. In theory this means the LED will have 100% light output when the dimmer is scaled at 10V, whilst 0% output at 0V. In reality, most sources will only achieve light levels down to 10-15% of their maximum output rather than zero due to the limitation of the power supply. A switch or relay is therefore needed to completely turn the light off.

What is Pulse Wave Modulation (PWM) Dimming?

PWM dimming is a form of Digital dimming. However instead of adjusting the DC current, PWM dimming varies the duty cycle of the constant current. It switches the input current of the LED lamp at a high frequency between 0A and the rated LED current. This interruption or modification of the on/off rate of the LED will result as a change of output percentage (dimming level).

PWM method is more suitable for LEDs that need to maintain colour consistency when dimmed down to lower than normal light levels, and applications where colour mixing is required. Dimming causes LEDs to experience a shift in the spectral power distribution (colour appearance) similar to that of an incandescent lamp. For example, if coloured LEDs in an array are used to produce white light, this amount of colour shift (particularly with red and yellow LED) may result in a distorted colour appearance compared to the desired white light being produced. In order to be compatible with a PWM dimmer, the power supply must be able to run the LED at a high enough frequency.

What is Digital Dimming?

a.DSI and DALI Control

DSI and DALI dimming methods were developed under the working principle of 0-10V analogue lighting control.

DSI (Digital Series Interface) dimming technology is uniquely owned by Tridonic®, and it is used for both control of LED interface or Electronic Fluorescent ballasts.

DSI is low voltage, enabling installations to utilise much thinner cables. Because each device has its own wire to the main controller (rather than part of a central network it does not need a separate address to be set, and therefore can be easily replaced. DSI can dim to “off”, therefore not requiring the mains switch to be switched off. DSI is also the precursor to the DALI dimming system.

DALI was developed based on DSI protocol and is now the most common type of commercial lighting control system, which is available from many different suppliers. Each DALI device has a memory, which contains its own settings. This allows DALI to operate without a central control point.

Whilst DSI has the requirement of needing a separate wire for each control channel, it has the advantage of eliminating the individual addressing aspect required with DALI.

b.Switch dimming

This is a stand-alone digital protocol. It is a cost effective solution that is commonly used for residential and hospitality systems. No central control system is required for this type of dimmer.

c.DMX Dimmer

DMX is a digital control system designed for RGB and RGBW colour changing lighting systems. Compared to other Dimming solutions, DMX allows compleprogramming to communicate to DMX devices through a ‘Data Bus’. It sends signals which can instruct fixtures to dim, or even rotate or change position, as may be required in theatre or stage / studio lighting applications that require special effects.

Does dimming affect the LED efficiency?

Dimming does not result in a loss of the LED efficiency. During dimming, the LEDs are still operated at the same voltage and current as during full light output. In addition, lamp life is not affected by dimming, as is sometimes the case with frequently dimmed fluorescent lighting. Rather, dimming LEDs may actually increase the useful life of LEDs, because dimming can reduce the operating temperature inside the fixture.

What are the main considerations in selecting an LED Driver?

1. Do not overload LED drivers. One of the most common mistakes is to connect too many LED strings in series. This may result in too low a voltage being available to the last string(s) in the sequence.

2. Use the correct Voltage Driver. If a wrong voltage driver is used, the LEDs may not work, or may operate at higher currents than specified by the manufacturer. Always check the voltage rating of the LED load being used against the rated output voltage of the driver. For example, using a 12V driver on a 10V LED load could result in significantly shorter life of the module.

3. Whilst most LEDs have the ability to start at temperatures as low as -40°C, operating them at these colder ambient temperatures can cause operating problems. LEDs draw higher power at colder ambient temperatures, which is opposite of what happens with fluorescent lamps. For outdoor applications where the power supply is mounted remotely, the maximum LED load on the driver should be reduced by up to 20 percent to avoid operation problems during colder temperatures.

4. Most LED drivers are for use in dry locations only. If used outdoors, drivers should be enclosed in a weatherproof enclosure. Drivers for wet locations are available, normally in a sealed enclosure, purposefully IP rated for mounting outdoors.

5. Drivers used / specified should always have short-circuit protection. In addition, drivers should be designed specifically for the given application. Generally, drivers that can handle higher temperature extremes are recommended, as sometimes the full installation details are not known at the time of purchase.

Australian owned Company

Australian owned Company